Machine Tending System

Purpose of Implementation

Machine tending is a solution in which robots automatically perform loading and unloading operations for various types of equipment, including machine tools, injection molding machines, and presses.

By automating repetitive, labor-intensive tasks, it aims to improve production line efficiency while reducing operator workload and workplace risks.

Expected Benefits

- 24/7 Uninterrupted Production

- Maximizes equipment utilization through automated loading and material handling during nights and holidays.

- Precise and Stable Quality Control

- Vision-based control ensures consistent quality even with positional deviations.

- Reduced Operating Costs and Workforce Upskilling

- Robots replace repetitive tasks, allowing human workers to focus on higher-value operations.

- Flexible Process Expansion

- Easily scalable to various parts and processes through integration with tool changers and AMRs.

Key Application Areas

- Automotive Parts Manufacturing

- Automated loading and unloading linked with press processing and inspection operations.

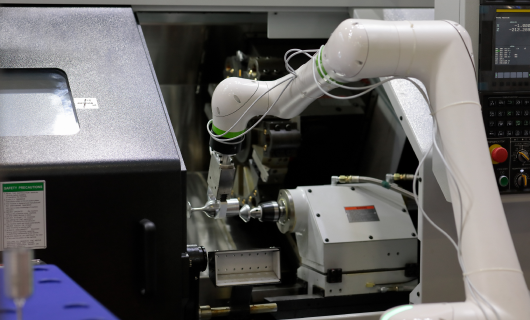

- Precision Machining

- Unmanned machining lines integrating CNC turning processes with vision inspection.

- Medical Device Injection Molding

- Automatic tray alignment and transfer after molding and cooling.

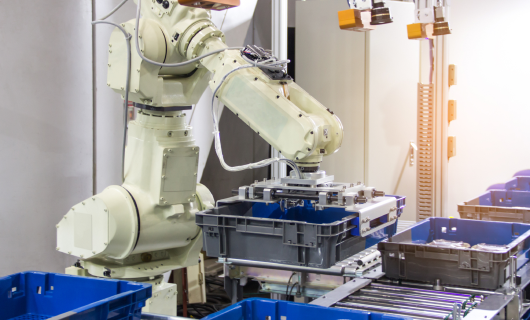

- Logistics Automation Integration

- Material supply and production line linkage using AMRs.

Reference

- CNC Lathe Machine Tending Automation

- High-precision automated loading for quartz ring machining using vacuum jigs and alignment technology, enabling 24/7 operation of up to 13 CNC machines with a single AMMR.

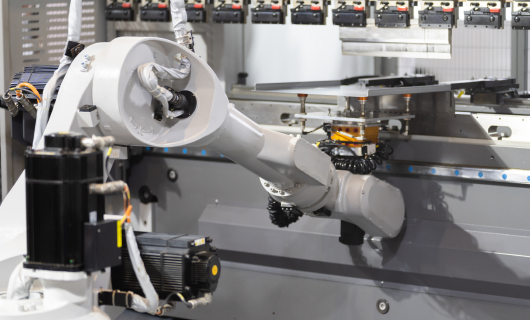

- Press Operation Automation (with Articulated Robot)

- End-to-end automation of press processes using an articulated robot, reducing manual labor in hazardous environments while improving safety and productivity.

- Automated Machine Tending Process

- Automation of access between process positions is achieved through side docking and undocking, along with crab-drive-based movement. Through tool change motions and 3D vision–based recognition of jig and FOUP positions, target objects are accurately picked up, and safe transfer operations are performed based on the recognized positions. Based on precise recognition and repetitive motions, the machine tending process is implemented in a stable manner.