Digital Twin

Purpose of Implementation

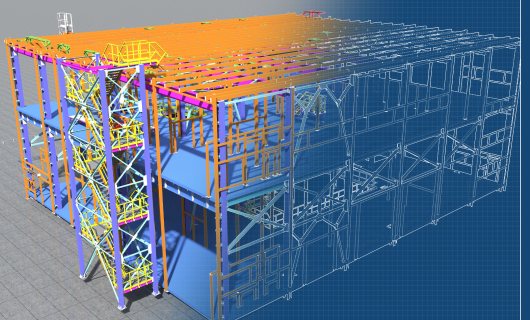

A digital twin is a technology that replicates physical spaces or equipment in a virtual environment, enabling realistic simulation and monitoring.

By reflecting real-time equipment conditions and production processes, it helps derive optimal operational strategies, reduce risks through pre-validation, and support efficient resource utilization.

Expected Benefits

- Process Simulation in a Virtual Environment

- Real-world equipment and processes are recreated as digital models, enabling advance validation and testing.

- Real-Time Operational Monitoring

- Visualization of current system status based on real-time data from physical operations.

- Predictive Maintenance Support

- Early detection of potential failures through simulation-based analysis.

- Data-Driven Decision Making

- Optimization of production planning and investment strategies using data-backed insights.

Key Applications

- Manufacturing Plants

- Prediction of bottlenecks and optimization of production lines.

- Logistics Centers

- Verification of logistics routes and material flow through simulation.

- Smart Cities

- Policy validation through digital modeling of traffic and facility operations.

- Large Commercial & Public Facilities

- Planning and optimization of building systems such as HVAC, equipment, and energy usage using virtual models.

Reference

- Digital Twin Development Based on Sectional Throughput Simulation

- A logistics system that automatically supplies battery trays to each process was modeled using a digital twin.

Material flow variations along the main conveyor line were analyzed by section to identify bottlenecks.

By optimizing line speed and diverter control conditions, logistics flow stability and overall process efficiency were significantly improved.