Visual Servoing

Purpose of Implementation

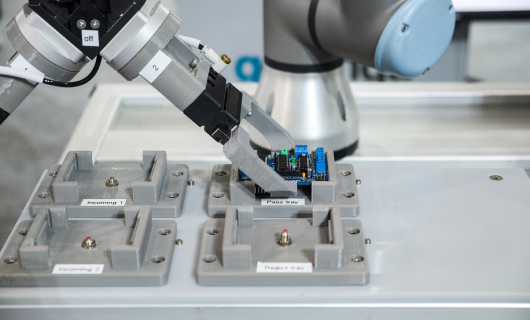

Visual servoing is a technology that recognizes targets using cameras and vision systems and controls robot motion in real time based on visual feedback.

It enables stable and flexible operation in precision processes by compensating for positional errors and adapting to environmental changes.

Expected Benefits

- Real-Time Visual Feedback Control

- Immediate correction of robot position and orientation using camera-based feedback.

- High-Precision Task Execution

- Automatic compensation for minor positional errors ensures stable performance in high-accuracy operations.

- Adaptability to Dynamic Environments

- Maintains reliable control even in frequently changing work conditions.

- Consistent Quality Assurance

- Continuous visual feedback enables stable and repeatable quality output.

Key Applications

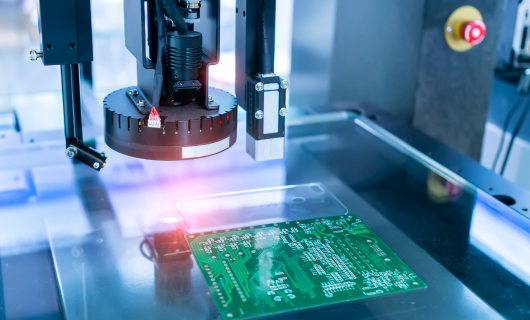

- Electronics & Precision Devices

- Precision assembly of PCBs and connectors, and handling of small components.

- Automotive Parts Manufacturing

- Assembly and welding position correction for irregularly arranged components.

- Food & Packaging Industries

- Real-time tracking and automated packaging of products moving on conveyors.

- Inspection & Testing

- Camera-based defect detection and robotic correction or rework operations.