Bin Picking

Purpose of Implementation

Bin picking automates complex picking processes that previously relied on manual visual inspection and human labor, with the goal of improving worker safety and maximizing productivity.

It enables automated handling of heavy or hazardous items and provides flexible operation even in high-mix, low-volume production environments.

Expected Benefits

- Automated Picking of Randomly Arranged Parts

- Accurate picking of unstructured parts using 3D vision technology.

- Increased Supply Speed

- Faster picking compared to manual work, reducing waiting time in downstream processes.

- Reduced Labor Costs

- Robots replace repetitive picking tasks, minimizing manual labor requirements.

- Precise and Stable Gripping

- Reliable picking of irregular parts without damage through precise gripping control.

Key Applications

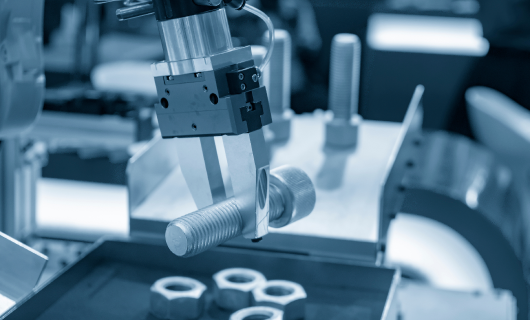

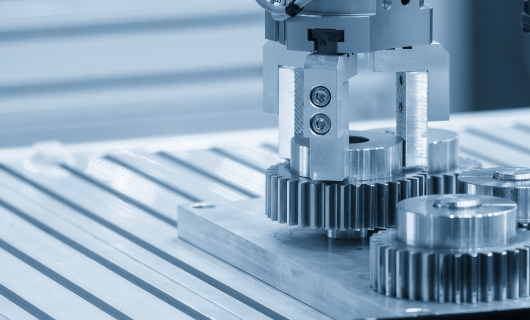

- Automotive Parts Manufacturing

- Automated picking of randomly stacked parts such as gears, bearings, and bolts.

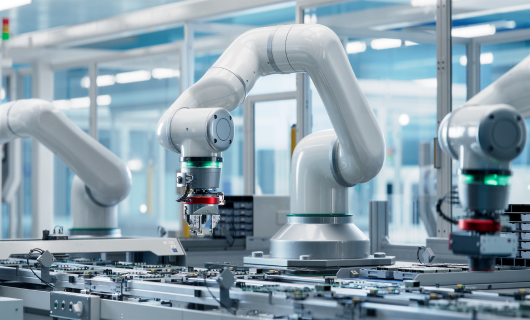

- Electronics Assembly Lines

- Automated feeding of small components including connectors and PCBs.

- Casting & Forging Processes

- Automated picking and transfer of high-temperature and heavy components.

- Warehouse Automation

- Automated sorting of packages located in random positions within logistics facilities.

Reference

- Box Picking

- To meet the requirement for organizing randomly placed boxes of various sizes onto shelves, 3D vision and AI-based recognition technologies are applied to identify the position and orientation of each box.

Stable pick-and-place operations are achieved using a robotic hand, enabling accurate handling of diverse boxes and improving automation efficiency in shelving and storage processes.